Post 33: Should You Seal Octave Vents?

Through the years I have heard many conversations and have been asked many times, “Should my octave vents be sealed?”

In short, we at Onks Woodwind Specialists believe you should seal octave vents after removing them from your oboe and/or English Horn.

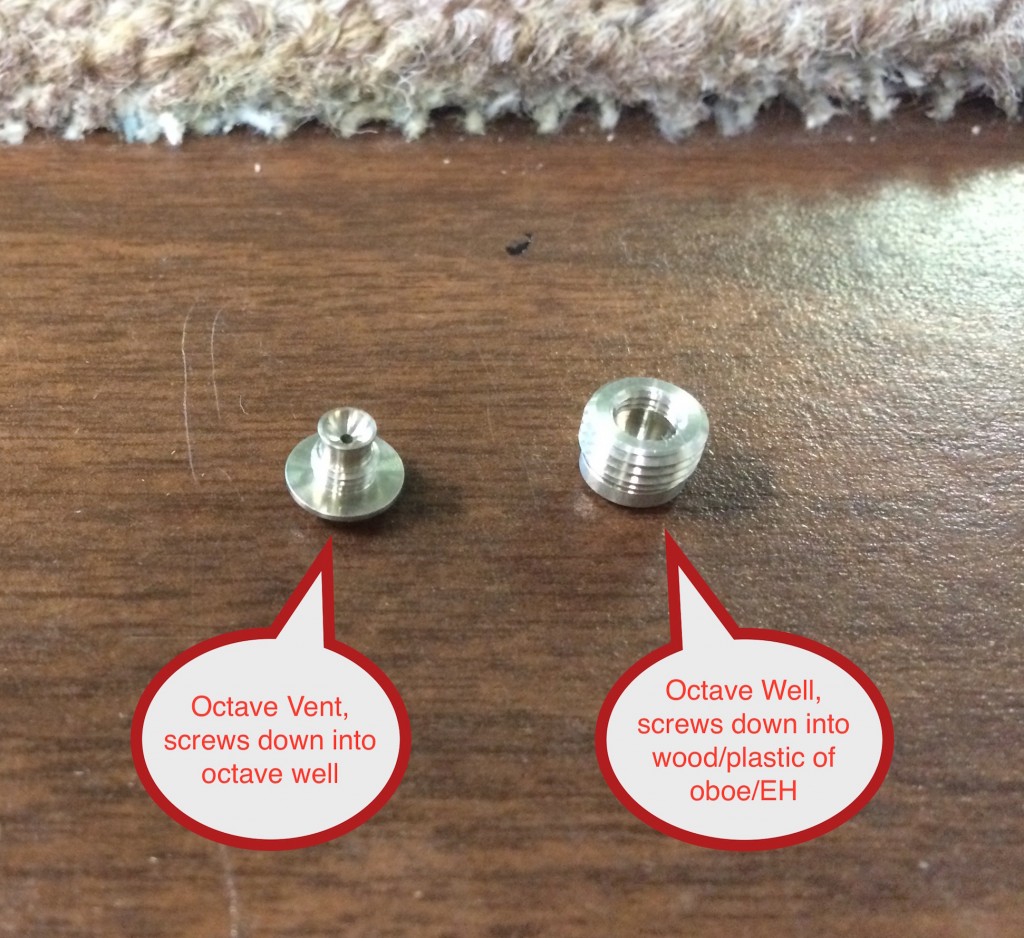

95 percent of octave vents are manufactured in two parts. The first part is the ‘octave vent well’ that is threaded on the outside so it can screw down “permanently” into the wood or plastic of the instrument. It is also threaded on the inside to accept the octave vent. The second part is the octave vent itself which is threaded on the outside and screws down into the well. In the picture below, you can see the vent and the well.

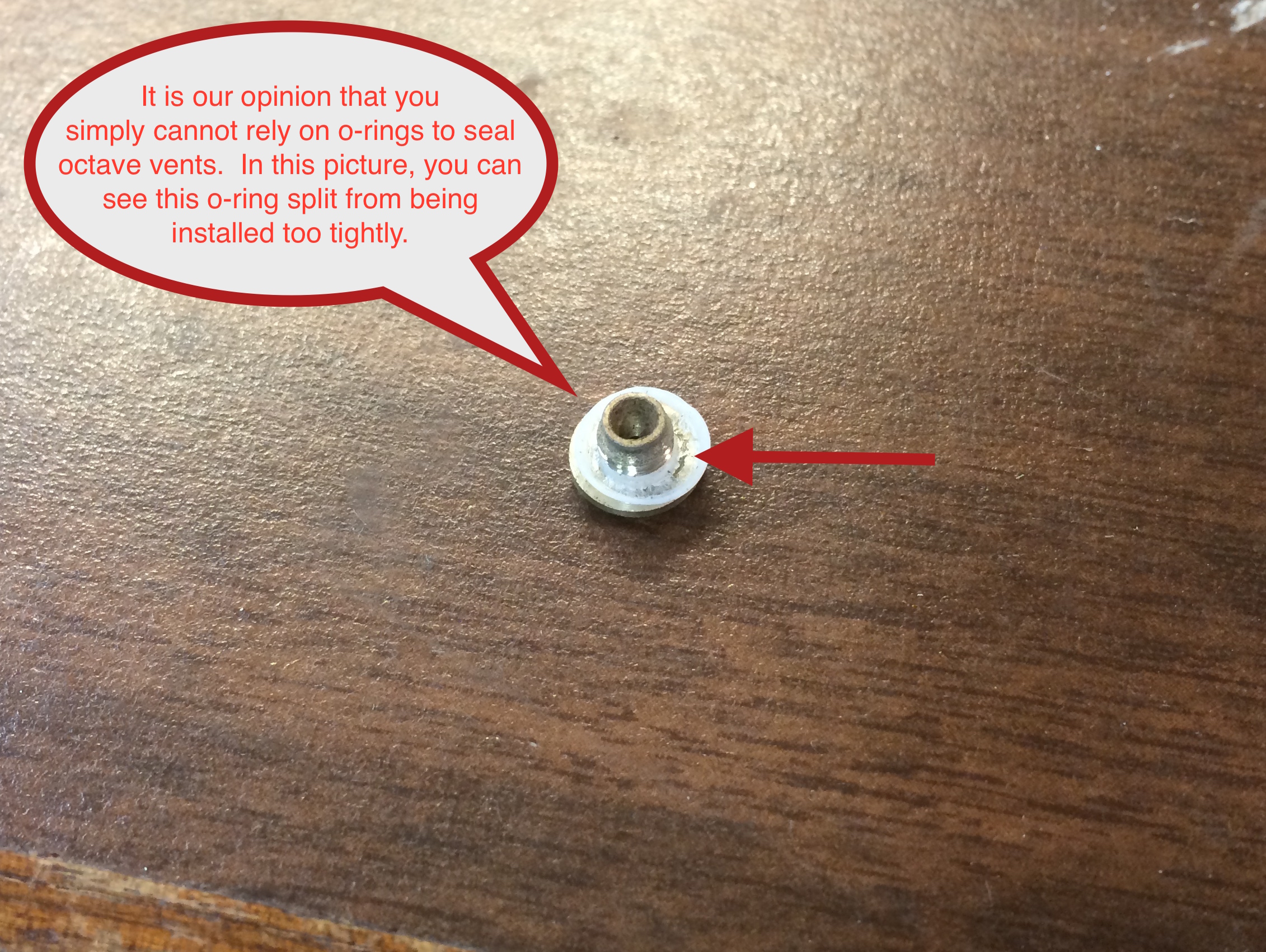

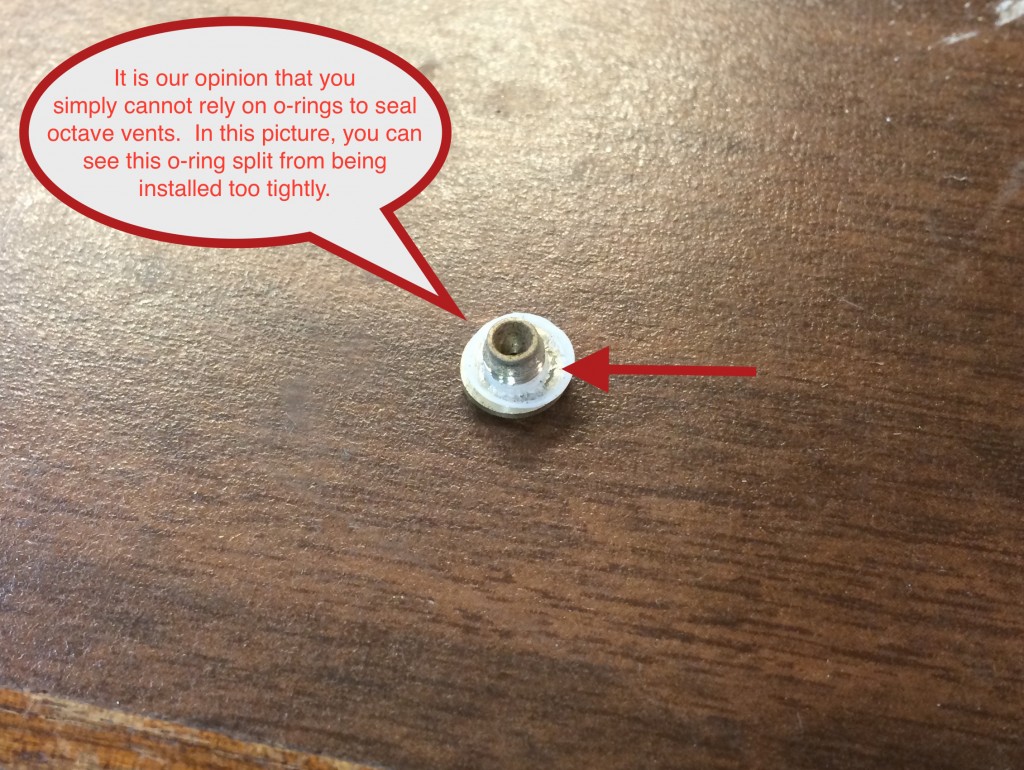

Because of the various threads that connect these two pieces, there will always be the potential for air to escape, which in turn adds one more place for your instrument to leak. In the picture below, you will see an o-ring that has been installed on the octave vent. In theory this o-ring seals the connection between the well and the vent. But, as you can see in this picture, this particular o-ring has been split through due to over tightening during the installation process. Over the past ten years of repairing oboes, most all of the o-rings I have seen have been like this one, split due to over tightening. Even if the o-ring seals the well to vent connection, there is no guarantee that the threads on the outside of the well are sealing. Due to these two factors, we always seal octave vents. It only takes thirty seconds to a minute and, once done, you are guaranteed to have an airtight seal on your octave vents.

Stay tuned for our next blog post about how to seal your octave vents.

Leave a Reply

Want to join the discussion?Feel free to contribute!